Toyota's New Motor Magnets Cut Dependence On Rare-Earth Materials For EVs

Highlights

- World's first neodymium-reduced, heat-resistant magnet developed

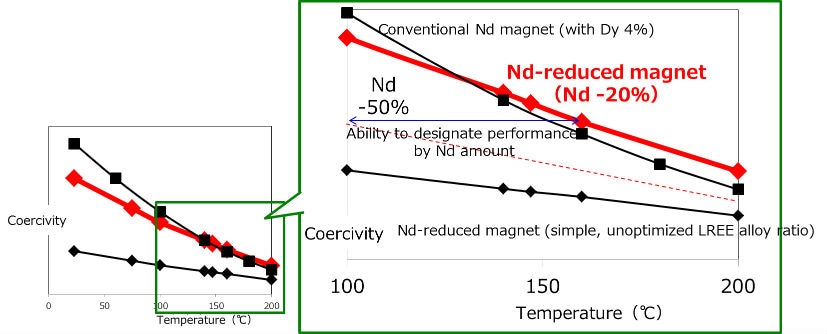

- Toyota's new magnets are cheaper, while maintaining the same coercivity

- The new magnets will be a key elements in the future to popularise EVs

Toyota Motor Corporation has announced that it has developed an electric vehicle motor magnet, which reduces the use of a rare-earth material neodymium by almost 50 per cent. Neodymium magnets are heat-resistant magnets used in high-output electric motors for electric vehicles, as well as machines and robots. With the use of EVs set to increase rapidly in the future, Toyota's new heat-resistant magnet has been designed to survive similar high temperature conditions. It will reduce the dependency on neodymium that will get harder to source in the years to come as its largest supplier, China, toughens its environmental regulations.

Toyota explains that rare-earth materials make up nearly 30 per cent of the elements in magnets used for electric vehicles. A majority of this includes neodymium, which helps magnets withstand high temperatures. Replacing neodymium, Toyota's new magnet uses lanthanum (La) and cerium (Ce), which are low-cost rare earth materials that are not only cheaper to source, but in more abundance as well. In addition, Toyota's new magnet also negates the use of dysprosium and terbium, two additional rare-earth elements that have been used in heat-resistant magnets for EVs.

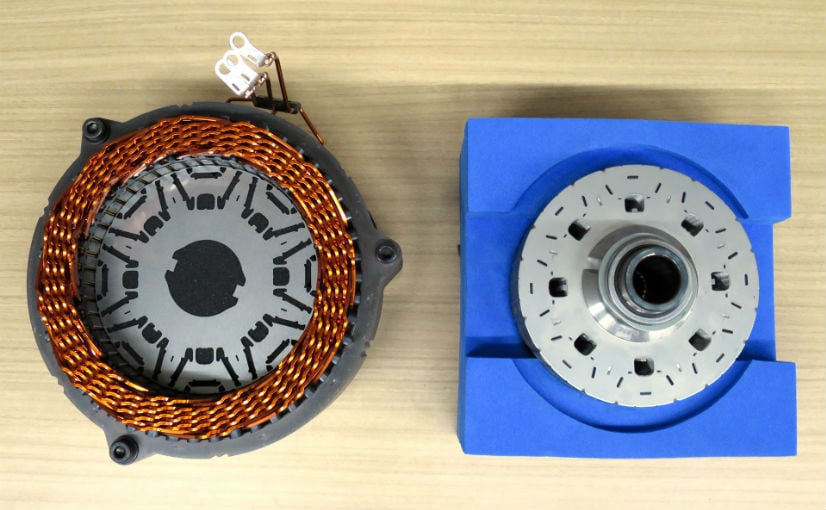

(Neodymium magnets used on the 4th Generation Toyota Prius)

While such a replacement would normally degrade the magnets' performance, especially under high temperatures, Toyota has adopted new technologies that include a two-layered magnet structure to ensure the new magnets retain their magnetism and heat resistance features, as good as the neodymium ones.

The Japanese auto giant says that the plan is to commercialize the components for power steering motors by the first half of the 2020s, while the magnets will be used for electric vehicles within a decade. The automaker is exploring technologies to mass produce the magnet and is in talks with magnet makers to commercialise the parts. The new magnets will not only be relatively cheaper, but will also help reduce the dependency on China which is said to produce 80 per cent of the world's neodymium.

(Toyota's magnets retains similar coercivity levels as neodymium magnets)

Interestingly though, Toyota isn't the only car maker concerned about the shortage of rare-earth materials. Honda has already been using a hybrid neodymium magnet, developed in collaboration with Daido Steel, which eliminates the need of dysprosium and terbium in the magnet. Honda already uses its hybrid magnets on several international models including the Freed, Jazz and Vezel.

Related Articles

Latest Reviews

Popular Toyota Models

Toyota FortunerEx-Showroom Price₹ 33.43 - 51.44 Lakh

Toyota FortunerEx-Showroom Price₹ 33.43 - 51.44 Lakh Toyota Innova CrystaEx-Showroom Price₹ 19.13 - 26.3 Lakh

Toyota Innova CrystaEx-Showroom Price₹ 19.13 - 26.3 Lakh Toyota RumionEx-Showroom Price₹ 10.44 - 13.73 Lakh

Toyota RumionEx-Showroom Price₹ 10.44 - 13.73 Lakh Toyota Urban Cruiser TaisorEx-Showroom Price₹ 7.74 - 13.04 Lakh

Toyota Urban Cruiser TaisorEx-Showroom Price₹ 7.74 - 13.04 Lakh Toyota Land CruiserEx-Showroom Price₹ 2.31 - 2.41 Crore

Toyota Land CruiserEx-Showroom Price₹ 2.31 - 2.41 Crore Toyota Urban Cruiser HyryderEx-Showroom Price₹ 11.14 - 20.19 Lakh

Toyota Urban Cruiser HyryderEx-Showroom Price₹ 11.14 - 20.19 Lakh Toyota Innova HycrossEx-Showroom Price₹ 19.09 - 31.34 Lakh

Toyota Innova HycrossEx-Showroom Price₹ 19.09 - 31.34 Lakh Toyota CamryEx-Showroom Price₹ 48 Lakh

Toyota CamryEx-Showroom Price₹ 48 Lakh Toyota GlanzaEx-Showroom Price₹ 6.81 - 10 Lakh

Toyota GlanzaEx-Showroom Price₹ 6.81 - 10 Lakh Toyota VellfireEx-Showroom Price₹ 1.22 - 1.33 Crore

Toyota VellfireEx-Showroom Price₹ 1.22 - 1.33 Crore Toyota Fortuner LegenderEx-Showroom Price₹ 43.66 - 47.64 Lakh

Toyota Fortuner LegenderEx-Showroom Price₹ 43.66 - 47.64 Lakh Toyota HiluxEx-Showroom Price₹ 30.4 - 37.9 Lakh

Toyota HiluxEx-Showroom Price₹ 30.4 - 37.9 Lakh

- Home

- Reviews

- Auto Industry

- Toyota's New Motor Magnets Reduce Dependence On Rare-Earth Materials For Electric Vehicles